Brochure

Download our brochure to discover more about us and our precision machining services.

Pdf FilesContact us ?

Meet the growing demands of global clients in the precision machine world

S. No. 29, 10-12, Narhe Ambegaon Rd, Dhayari, Pune, Maharashtra 411041

(020) 246-908-88

CNC Turning Service

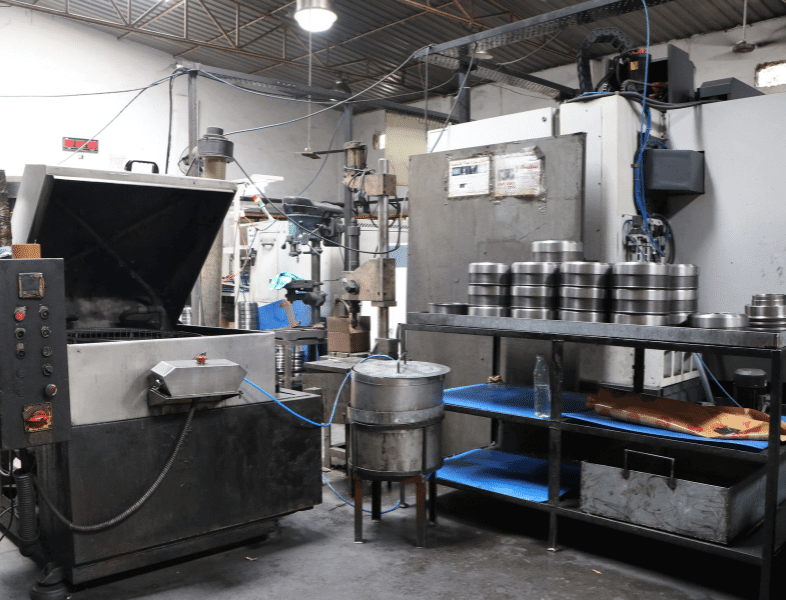

Craft And Technik Industries founded in 1996 is dedicated to supplying high-quality CNC turned components with an unwavering commitment to excellence and service.

From raw material procurement through precision machining and sub-assemblies with severe critical tolerances, demanding quality and traceability standards, documentation, and guaranteed on-time delivery, we are indeed a one-stop solution.

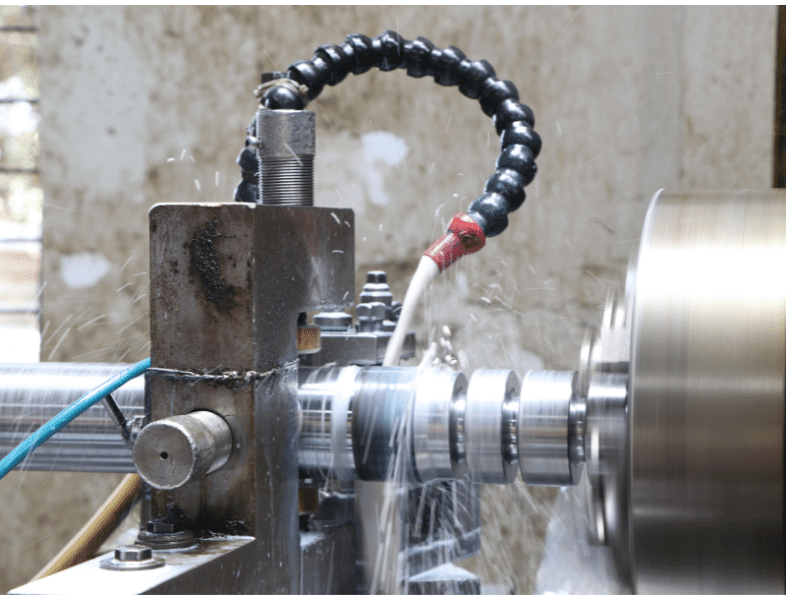

CATI’s CNC turning services assist you in producing CNC turned components for a variety of materials with great precision.

Precision CNC turning services specification

We treat inspection as a part of the process, using air plug gauges and standard plug gauges for in-line inspections.

- We focus on the following industries: Automobile, power generation, and industrial refrigeration.

- Materials used: Cast Iron, Ductile Iron, CF3 Steel, Low Carbon Steel, Aluminum Bronze, Silicon Bross, etc.

- Tolerances: 0.005 mm.

- CNC max part diameter: 350 mm.

- CNC max part length: 350 mm.

Our Best Solutions

Advanced Technology

Expert Process Engineers

Best Quality Components

On – Time Delivery

What We Do?

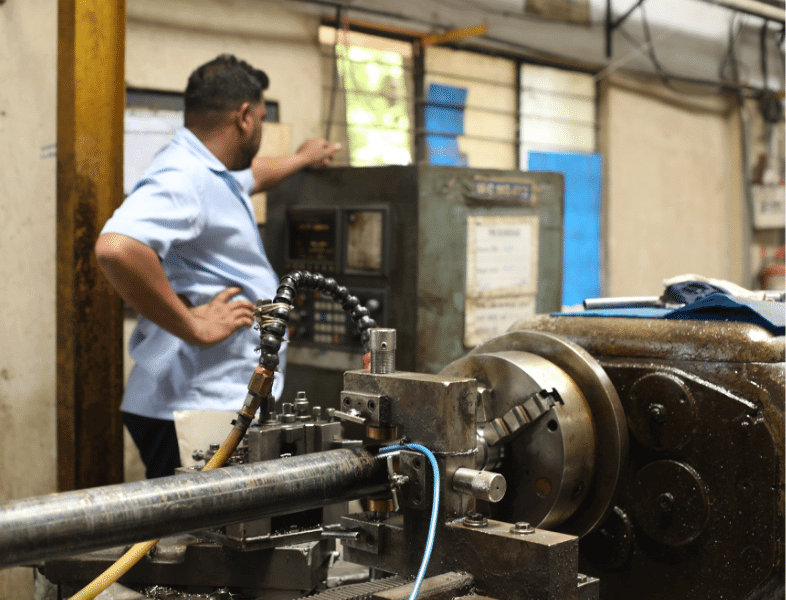

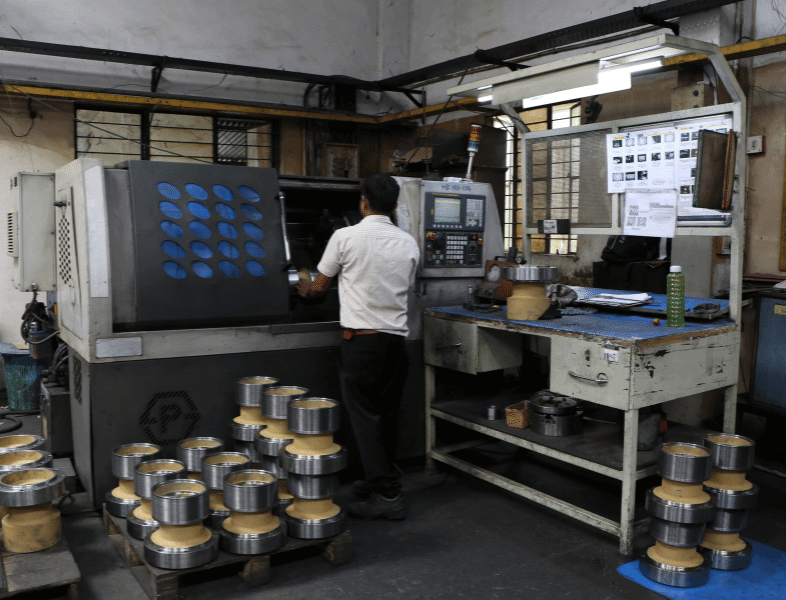

CATI produces high-quality turned components and milled components for its customers using CNC machining technology that will meet customers project requirements from low volume production batches to high volumes of 1500+ numbers per day. Our machines have the finest machining capabilities and can guarantee your strict tolerance standards.

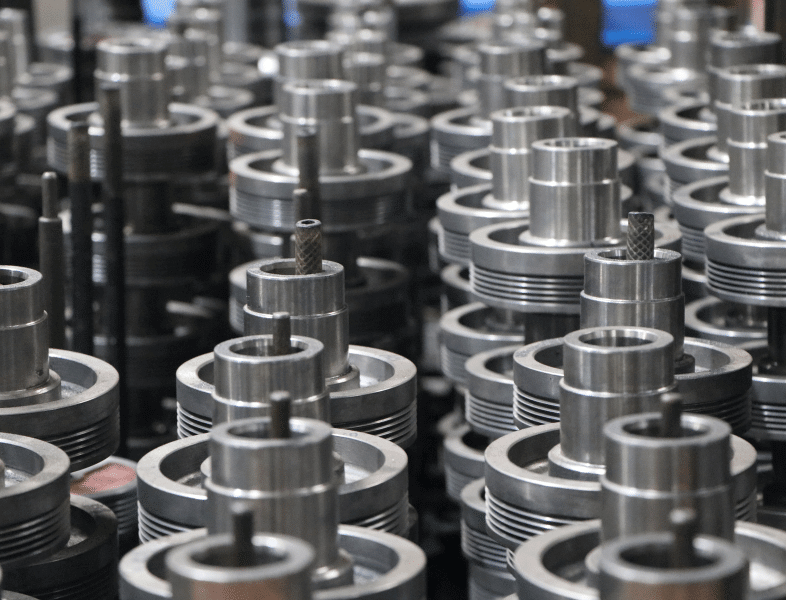

We are a leading manufacturer of pulleys in India. We bring forth vast industrial experience and expertise in this business, involved in offering a high-quality range of idler pulleys, single v groove pulleys, double v groove pulleys, single poly groove pulleys, double poly groove pulleys, crank adaptors, and accessory drive pulleys.

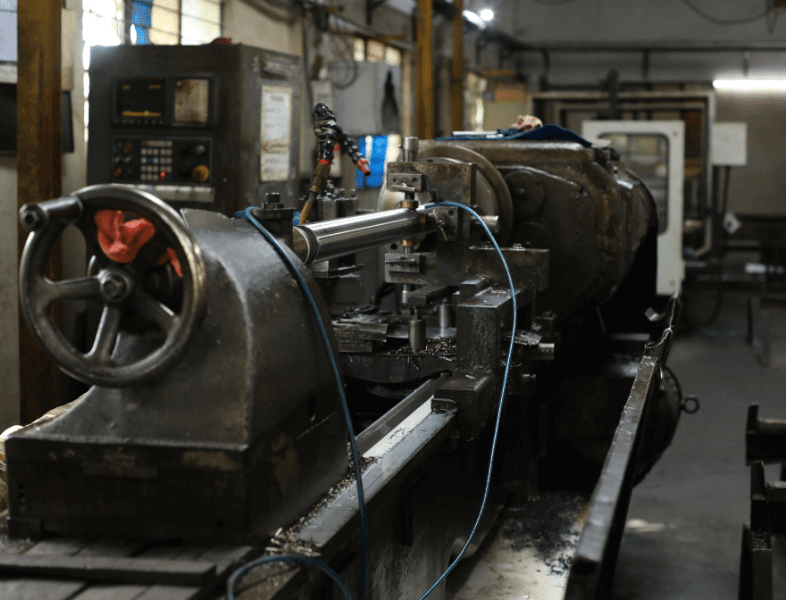

We make precise CNC & traditional turning projects.

We operate in a climate-controlled facility to assure the best quality and precision for our clients, allowing us to hold tolerances of +/-.0002 inches: As a consequence, our precise CNC and traditional turning projects consistently meet or exceed our clients’ expectations.

We offer design services that associated with our operations

We offer CAD design services, CAM programming services, and reverse engineering to further support clients with state-of-the-art technology

We provide additional services for our customers.

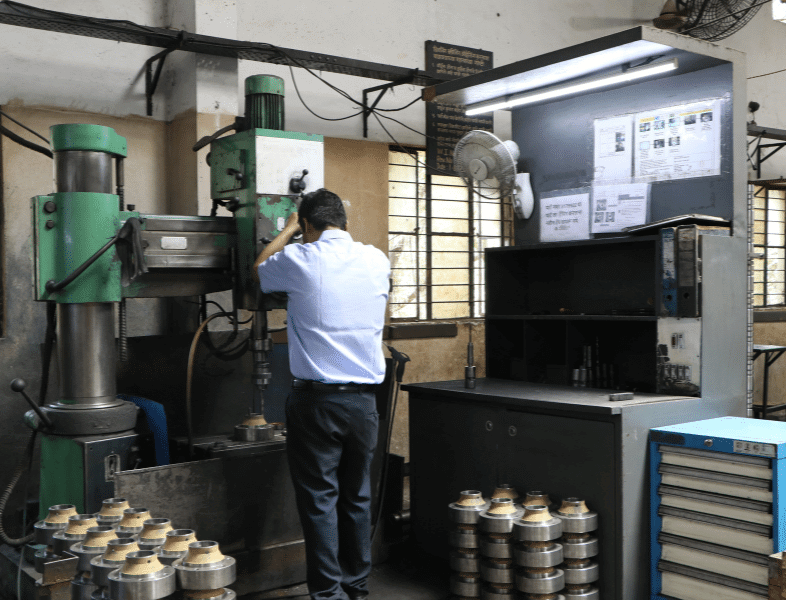

In addition to precise CNC and traditional turning, we also provide grinding and balancing services, as well as bending.

Machine Specifications

CNC Turning with Tail Stock

Machine Name: CNC Turning with Tail Stock

Make: Sands Precision, Bangalore

Total No. of Machines – 9 nos.

Chuck Dia. 200 mm. – 3 nos.

Chuck Dia. 250 mm. – 5 nos.

Chuck Dia. 360 mm. – 1 no.

| Machine Details – | ||||

| Chuck Size | 200 mm. / 250 mm. / 360 mm. | |||

| Power | 12 / 20 kVa – Continuous 15 / 25 kVa – for 30 mins. |

|||

| Max Turning Diameter | 250 mm. / 350mm. / 420mm. | |||

| Travel- | ||||

| X-Axis Stroke | 180 mm. – 230 mm. | |||

| Y-Axis Stroke | 540 mm. – 1235 mm. | |||

| Spindle Nose Taper | A2-5 / A2-6 / A2-8 | |||

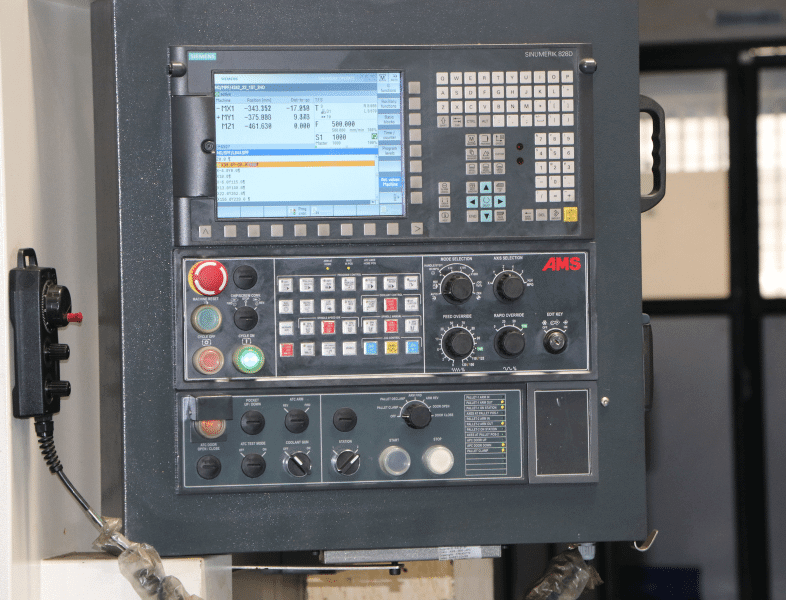

| Control System- | ||||

| CNC System | FANUC 0iMF / Siemens 820D | |||

| Tool Changer- | ||||

| ATC | Pragati Make – 8 Station | |||

| Accuracy- | ||||

| Positioning | ± 0.008 mm. | |||

| Repeatability | ± 0.003 mm. | |||